How Do You Decide Which Weld Joint to Use

You can weld sophisticated metal joints with MIG using either shielding gas or flux. A shut weld is a kind of joint where the two pieces thatll be became a member of are touching throughout the welding process.

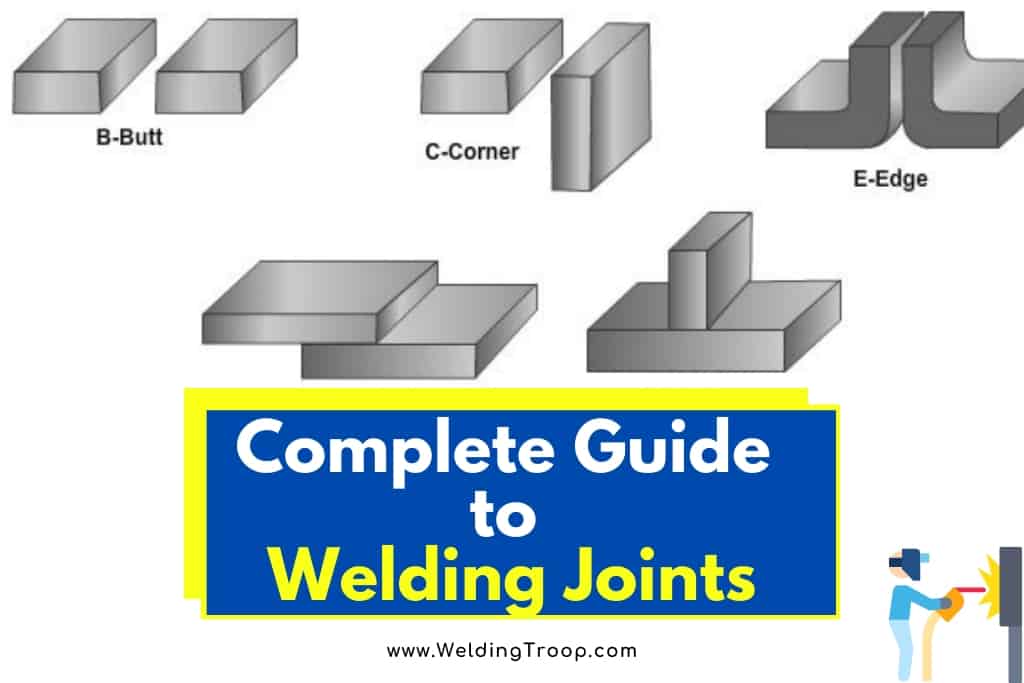

Welding Joint Types Butt Joints Lap Joints Tee Joints More

You may want to remove a weld for one of three reasons.

. The second reason may have something to do with salvaging a valuable part from a previously welded assembly. International standards do not generally provide requirements or guidance on minimum fillet weld sizes. Association rules may specify which type of welding to use.

If meshing with 2-D Shell elements or meshing with 3-D solids if. The corresponding internal flat seam is drawn in and its height is determined. If you still decide to use a hand grinder you can check the manual that comes with it once you purchase and follow the steps to weld your pipe.

The last one is to destroy a welded joint between two or more different parts. In welding selecting the welding rods sizes is one of the keys to a successful result. Several factors determine the type of welding you should use to construct a roll cage.

The hotter you set the welder the more likely it that the weld will penetrate and the joint will hold when you have finished. Hold the welded item you want to measure in one hand and hold the fillet weld gauge in the other. If youre planning to get into welding you must choose the welding method that fits your needs and helps you do your job well.

You want the protrusion located in. A weld seam that has a convex shape elevation 0 is called a cambered seam. Once you have determined that you must install a roll cage how do you decide whether to Mig weld or Tig weld the joints.

In such cases one should get back to the designer. This small amount of time practicing will save your hours of time grinding out your. When selecting the size of fillet weld for plate or pipe to achieve full strength weld apply below rules for fillet weld leg length.

If you import in FEMAP a solid model as Parasolid you need to decide the GEOMETRY IDEALIZATION TYPE you want to follow. If you are not sure what amperage to use with a certain piece of material whether thick or thin aluminum or steel it is always a good idea to practice a weld bead on a scrap piece of material similar to the final metal workpiece you intend to weld. A large weld area will require a larger cup size as more gas will be required to fill the puddle.

For example if material thickness. If you are unable to get close to the weld joint you will need a small TIG cup size to get inside of. How do you Decide.

Failing this as a rule-of-thumb at least two passes should be deposited with a minimum leg length of 6mm 14in considering that the first run is likely to be defective. As mentioned above welds are strong and if you want to undo the thin sheets joint together you have to drill or grind off the bead to crack it open. To create a strong butt weld you first choose the proper joint type needed to make sure you achieve full penetration of both metal faces and that the gap between the two typically set at about 18th of an inch apart can be filled fully with whatever your filler material is while maintaining the proper angle.

It is important to select a fillet weld gauge based on the specified thickness you need to measure. Can you get close to the weld joint. A small weld area can use a smaller TIG cup size as less gas is needed to weld the joint.

Before we begin ensure that some of the basic factors for selecting the welding rods are taken into consideration like what is. A dual welded butt joint is produced once the weld continues to be welded from each side. Positions you will be welding.

You want to move as few parts of your body and the welding gun as possible so that everything is steady and flows smoothly. With double welding the depths of every weld can differ slightly. You want to use both hands on the welding gun or use your off-hands wrist to guide your other hand.

Next think of your hand position. Mig or Tig Welding for a Roll Cage. If you work with metal sheets that are 1mm or 2mm thick it is best to use 16mm diameter electrodes.

In order to decide which process suits you the best for undoing a weld you need to determine the type of base metal. The Required Joint Design. Do a few practice runs with the welder turned off before beginning to weld.

These types of butt welds are the square joint v joint u joint and the j joint. The main focus must be to take the structures change of stiffness into account and if it is greatly influenced by the weld then this must be considered. And since there is a great variety of models and types of electrodes a series of aspects must be considered when selecting it.

The Welding Equipment and its Capacity Amps. The actual weld thickness is determined as the height of the triangle between the root and the two transitions between the weld the camber and the base material. The size of the weld area will determine how big of a cup you need.

TorchPlasma Cutter Another way you can bevel a pipe is with a torch cutter or a plasma cutter but this method is also similar to the hand grinder and requires you to cut the angle with your hand. The Required Regulatory Codes and Specifications. The most common one is to undo a bad weld or loose joint.

Minimum size of Leg length of fillet shall be 34 or 07 of the material thickness. The Tensile Strength. The type of material used to make the roll.

The MIG welding method is arguably the most convenient method to learn especially if youre just starting your welding journey. Horizontal Position Your welder is pointing up around forty degrees and tilted around twenty-five degrees towards the weld in this position.

How To Weld Five Basic Welding Joints Welding Diy Welding Metal Workshop

Comments

Post a Comment